When riding around on your steed for a few weeks or months dirt and dust build up, often in places that are hard to see despite good cleaning post ride. The consequence of this is that parts of the bike can start to creak and groan slightly. These creaks occur when two surfaces have dust between them and move around, or there is lack of lubrication on surfaces that should move (bearings). The headset area is a classic zone where creaks can take place and is often vulnerable to ingress from dust and dirt.

This is a simple procedure with Bagnoli Bike to show you how to dismantle and clean your headset then re-grease it to keep it running quietly and creak free.

Tools: Bike Stand, Allen wrenches, grease, torque wrench.

Remove the front wheel from the bike.

Unscrew the top cap of the headset.

Check the star washer is still in good shape and wedged properly.

Loosen the stem bolts and then remove the stem.

Make sure you hold the fork so it doesn’t suddenly fall out.

Retrieve the top cap and ensure the bearings don’t become dislodged.

Lastly, make sure that you don’t damage the lower bearing race or pull it out when you remove the steerer tube.

Clean the top surface of the headset.

Inspect the lower part of the steerer and the lower race support, then clean it with a rag.

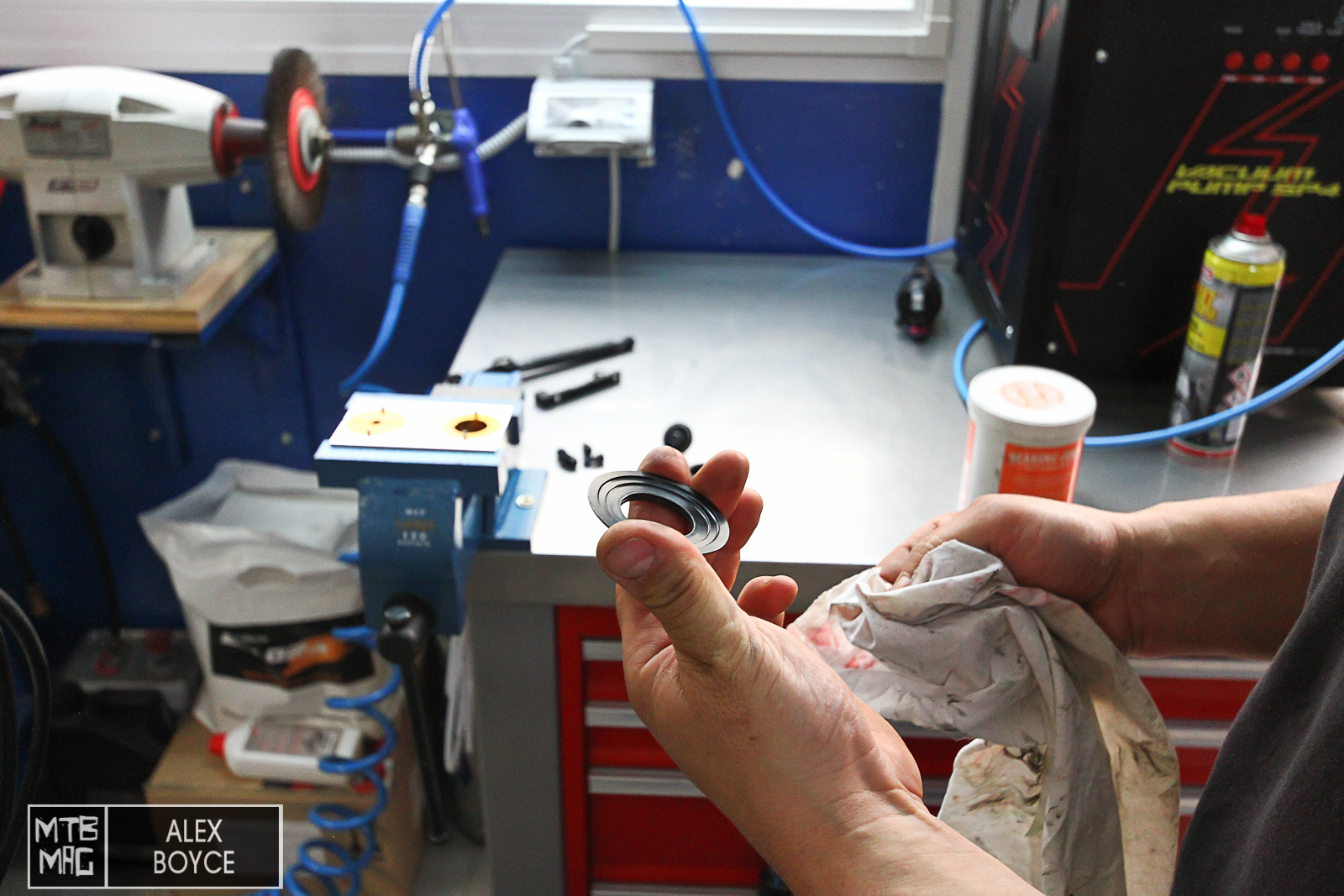

Remove the top bearings and the lower bearings and clean. Don’t use degreaser or WD40, it will strip out the grease from the bearing cases. Also make sure that the bearings are still running smoothly, if they are rough or apparently dry, replace them.

Now re-grease the bearing cups and place the bearings in the headset.

Use a specific grease like Juice Lubes “Bearing Juice,” or similar.

Give a final smear of grease to the surfaces of each bearing area after you placed them back into the headset.

Replace all the parts and refit the forks.

Once refitted, re-tighten the top cap to around 4 NM with a torque wrench. The bars should move smoothly and not be hard to move.

Once the bar is straight, you tighten the stem clamp bolts also using a torque wrench to around 5NM, any tighter and the stem clamp bolts or stem might be damaged, and if too loose the bar might move under tension, and cause an accident. If you crash ever, always recheck the stem clamp bolts to make sure they are correctly torqued.