[ad3]

Recently we had a rather beaten up Punta Ala Trail Center rental bike pass through our mechanic’s hands, requiring some love on the wheels. The rear wheel warranted a complete rim replacement and the front needed some time in the truing stand. Luckily the bends and hops were possible to remove with some wheel spoke re-tensioning, which we show you below.

Tools: Spoke key, truing stand.

This was the rear wheel, we removed the whole rim, it’s pretty impossible to straighten this wheel. (wheel rebuild coming up soon).

This was the front wheel, it has some dings and is not really that true, so we set to work on straightening it.

First remove the wheel, tyre and rim tape.

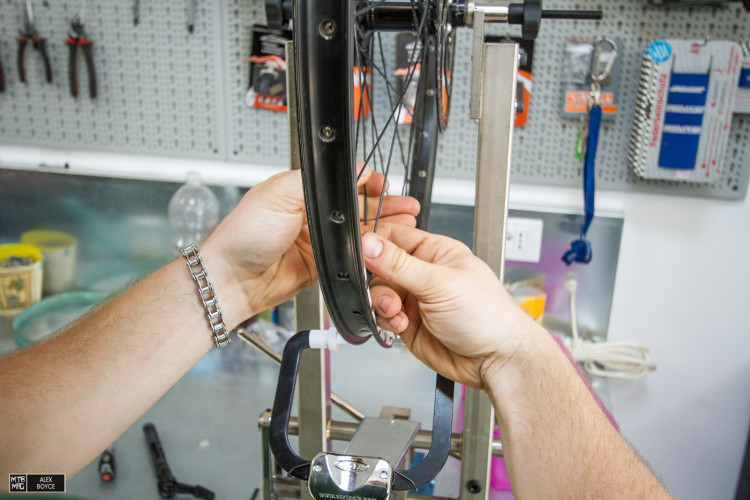

Put the wheel in the truing stand and make sure you have the correct spoke key for the spoke nipples. You can see the wheel is not straight at this point and sits far to the left.

We identify where it’s off center by rotating the wheel and seeing where the rim touches the indicators on the stand. Notice also the rim dent, not much can be done about that. A feel of the spokes tells us some are tight & some are loose.

We check the spoke tension by hand, in this case we find that one side (right) is quite tight compared to the other. We can’t tighten it or loosen much more. This wheel is on the limit of being recovered but we’ll try to see if it can limp along for a bit more.

At this point we realize the only way to bring some normal tension to the spokes is to loosen the spokes between one half to one whole turn on each side of the wheel directly opposing the damaged area.

Recovering extreme bends like this can be bit of a dark art. By loosening the opposing spokes we keep the wheel from being pulled too far out of round, by over tightening the spokes compared to the bent side which are now loose. Our aim is to re-tighten and balance all the spokes, shifting the wheel to a point where the spoke tension is not too extreme and keep the wheel as round as possible.

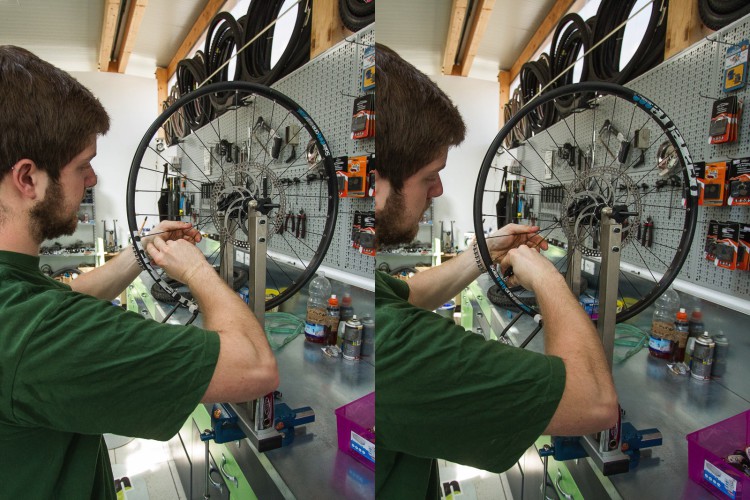

We tighten the spokes on the opposite side now, pulling the rim back over to the right.

Remember to tighten the spokes on the side that you want the rim to move towards. Do this in 1/4-1/2 turns at a time… no extreme movements. Also try to work in pairs of spokes. Loosen spokes that are under too much tension 1/4 turn at a time, always re-checking to see how much each adjustment affects how true the wheel is. Loosen also opposing spokes if you are worried about making spokes too tight.

We manage to get the rim back over. We loosened and tightened around 4 spokes around the general area that the wheel was bent.

As we loosened the other side a bit, we now start to re-tighten the other spokes on the opposite side of the wheel checking it stays true. Here we re-tighten both sides equally opposing the bit we are working on.

We check the rest of the spokes on the wheel to see if any became too loose during our tighten phase. If they are loose, we tighten them equally by a 1/4 turn at a time. Keep in mind, this is all a bit of an art and a balancing act. You have to constantly spin the wheel, fine tuning until it is about as round as it get. To keep a wheel straight and round, spokes need to be tightened in pairs, to avoid high spots.

We remount the tyre, inflate and ride briefly to see that the wheel is holding shape.

Mechanic @ Punta Ala Trail Center