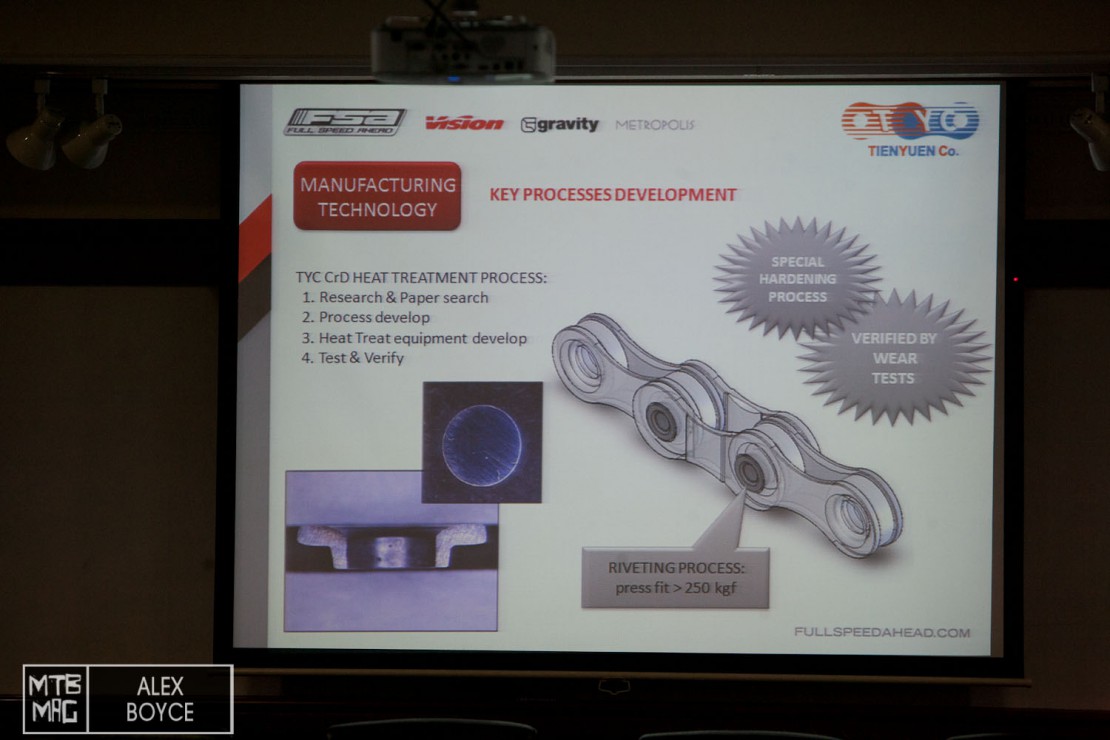

Our recent trip to Taiwan was originally programmed so we could visit a chain factory where FSA produces their top line components and their 11 speed chain. The reason for a chain factory seems to be based on the idea that something bigger might be coming from FSA in the near future, but with nothing confirmed we had be content with just chains.

The chain is one of those components that if you dont have it, it might be difficult to actually move the bike, it is also a very sensitive component that has to take all the force the rider applies, plus be resistant to wear in often dirty wet conditions. Therefore is was by default going to be interesting to see how the are made.

Our factory visit took place in a very traditional factory in Taichung, Taiwan. It was like stepping back in time to see this factory in the sense that it was serious, no pictures of bike riders, no “we ride as well” feeling, just production and attention to detail. In fact it was reassuring to know that such components are made with such seriousness. At least we know they are unlikely to fail when we need them the most.

Chain Production Tour

We had a look around the factory in great detail but had to be careful what we shot as there were a lot of trade secrets to see, but in general we were shown a good range of the process.

We managed to see what we could and shoot what we could in the production facility, it was an education about what companies do to safeguard their products. REst assured we think that the FSA chain will probably be as reliable as all the others and is a top line product straight out of the door.

Non Water Marked Photos : Courtesy FSA.